Gyprock Cinema Wall Systems are designed to provide a high performance wall where acoustic separation and a dramatic reduction in sound transmission is required such as between theatres in a cinema complex.

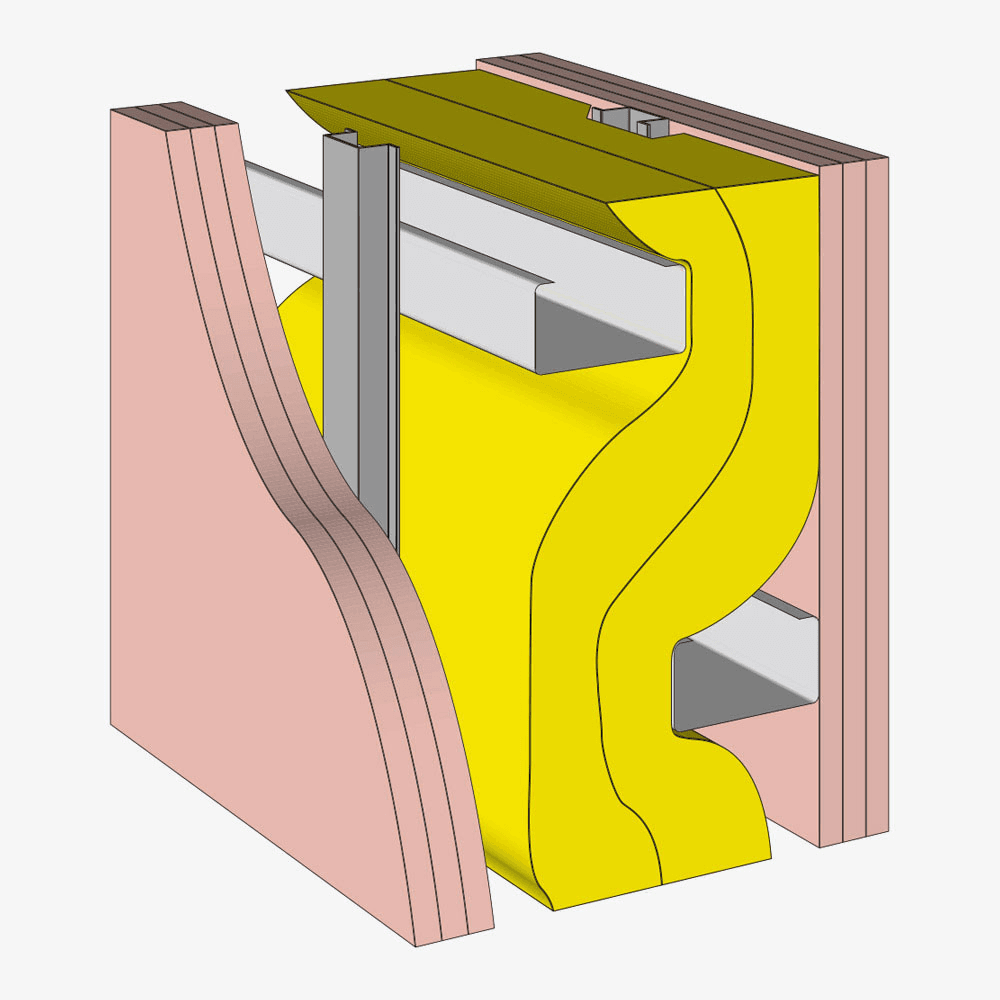

Gyprock Cinema Wall systems use a combination of framing, insulation and lining products to achieve superior acoustic performance. These high performance systems achieve a sound reduction of up to 81 Rw and are also highly fire resistant (FRL 120/120/120).

Applications

Gyprock Cinema Walls are specifically designed to achieve high levels of acoustic separation and are commonly used in multi-theatre cinema complexes and to reduce sound transfer around lecture halls, drama theatres and concert venues.

System Advantages

- Highly cost effective

- Can use the existing roof supporting steel columns

- Excellent Sound Transmission Loss (STL), particularly at low frequencies.

- Lightweight components for easy construction

- Fast screw fixing

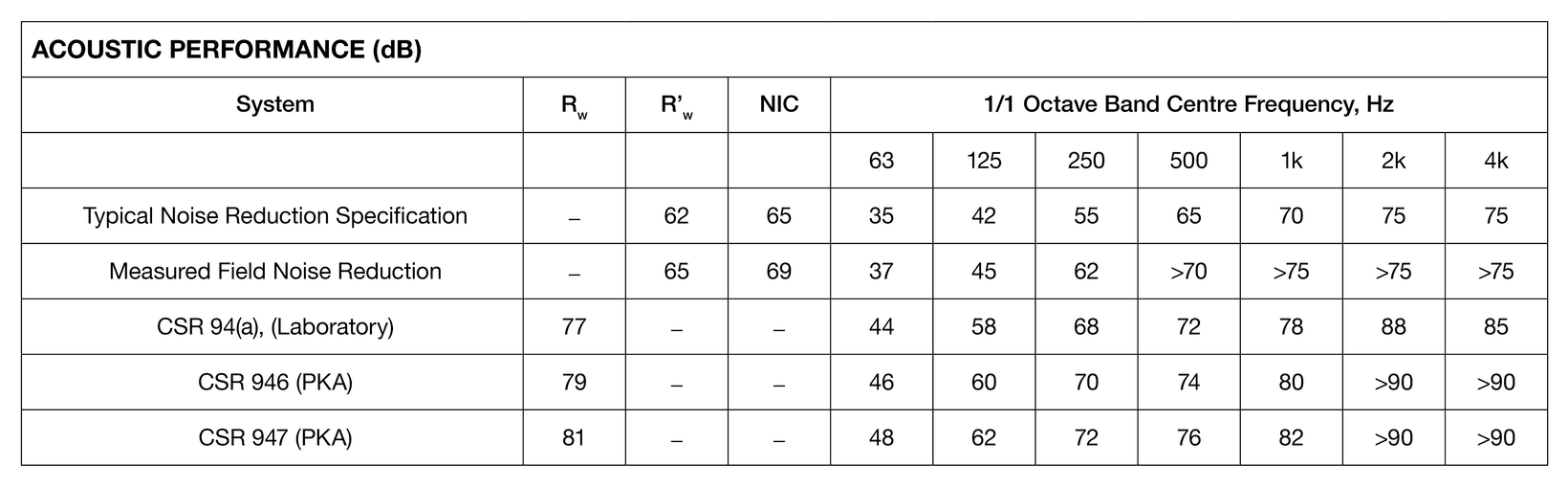

System Performance

The Gyprock Cinema Wall system has been tested at the National Acoustic Laboratories to assess its acoustic performance.

Loading component...

Loading component...

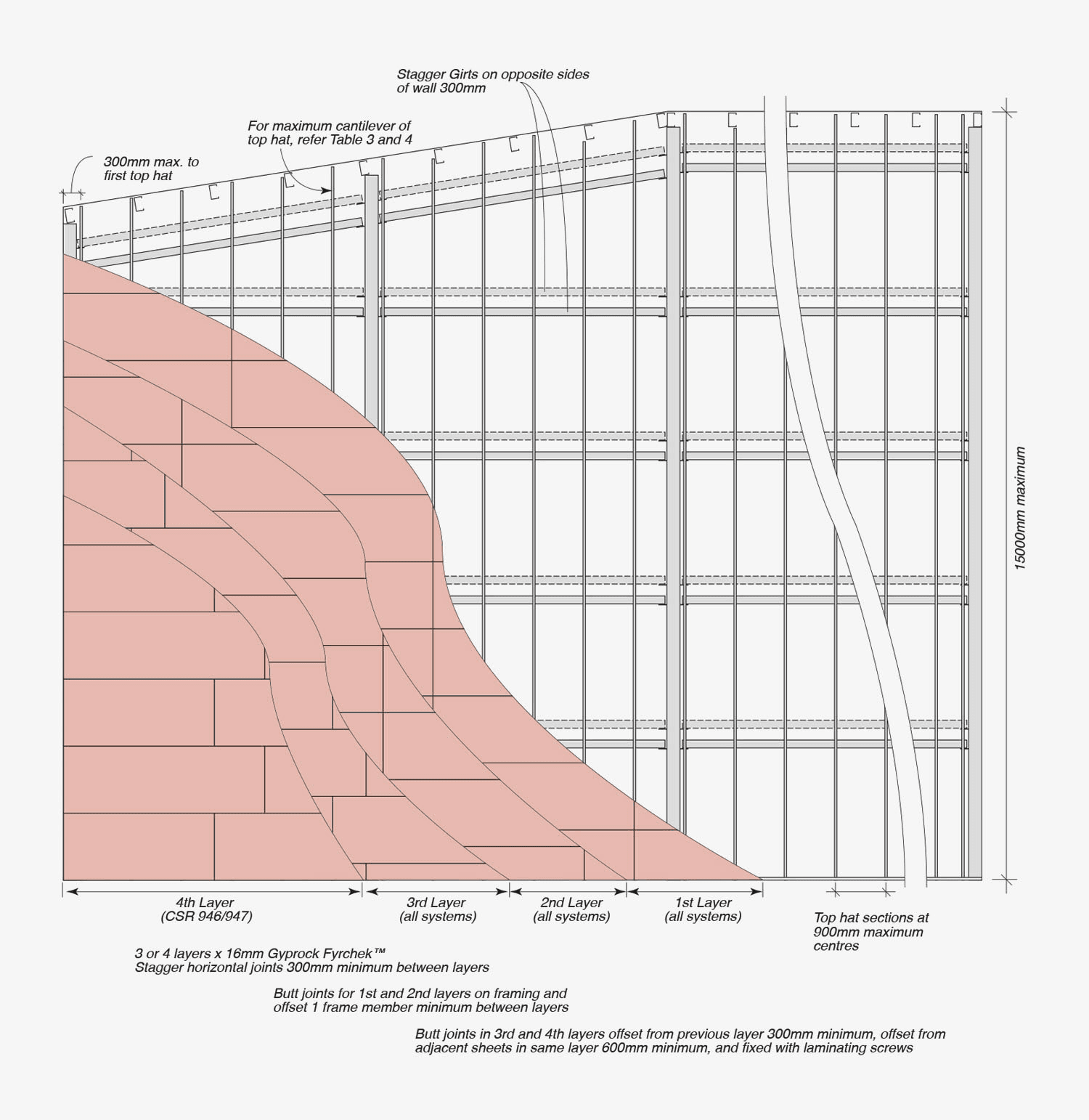

System Design

These diagrams show three typical layout options for the StrataWall system. The Gyprock Red Book outlines a comprehensive list of layout options and can help you find a design that works best for your building performance needs.

Loading component...

Loading component...

System Components

Gyprock Shaft Wall systems include a range of lining, insulation and accessory options to be determined by the designer in order to achieve different performance requirements. Only those product options specified should be used in order to guarantee the fire and acoustic performance of the system.