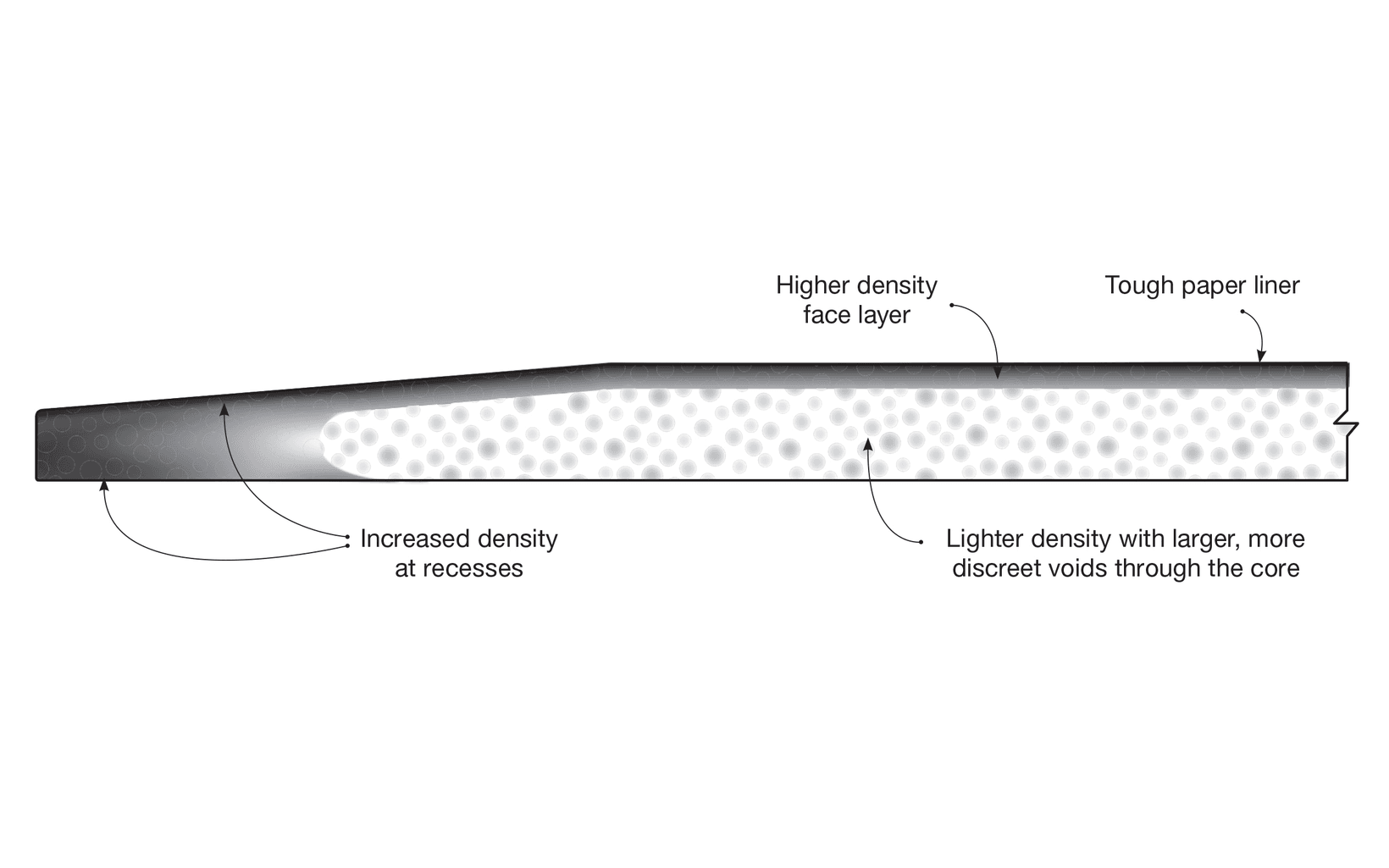

Head and shoulders above the rest, Gyprock Supaceil sets the standard for plasterboard in ceilings. This lightweight 10mm thick plasterboard features Optimised Core technology to provide significantly improved strength, handling and board performance.

Product Overview

Gyprock Supaceil was the first product in Australia manufactured with Optimised Core technology which provides an advanced performance-to-weight ratio, meaning greater breaking strength in a substantially lighter board that continues to exceed the performance requirements of Australian Standard AS/NZS 2588. This improved strength ensures it will stay flatter, even when installed on ceiling joists with 600mm centres. There is also less chance of fixings pulling through the board when extra pressure from above is applied such as heavy ceiling insulation.The board’s thicker face paper produces a crisper score and snap experience with cleaner cuts and squarer edges.

Loading component...

Loading component...

Typical Applications

Gyprock Supaceil is typically used as a superior ceiling lining option in residential applications and can be used to span up to 600mm joist centres. It is most suitable for areas of the home where exposure to moisture is not a concern such as bedrooms, living areas and entranceways.

Key Features

Australian Made

Licensed by Australian Made Campaign Ltd

Stronger

Superior breaking strength

Lighter

Easy to lift and flex for better sheet manoeuvrability

Improved score and snap

For crisp edges and cleaner cuts