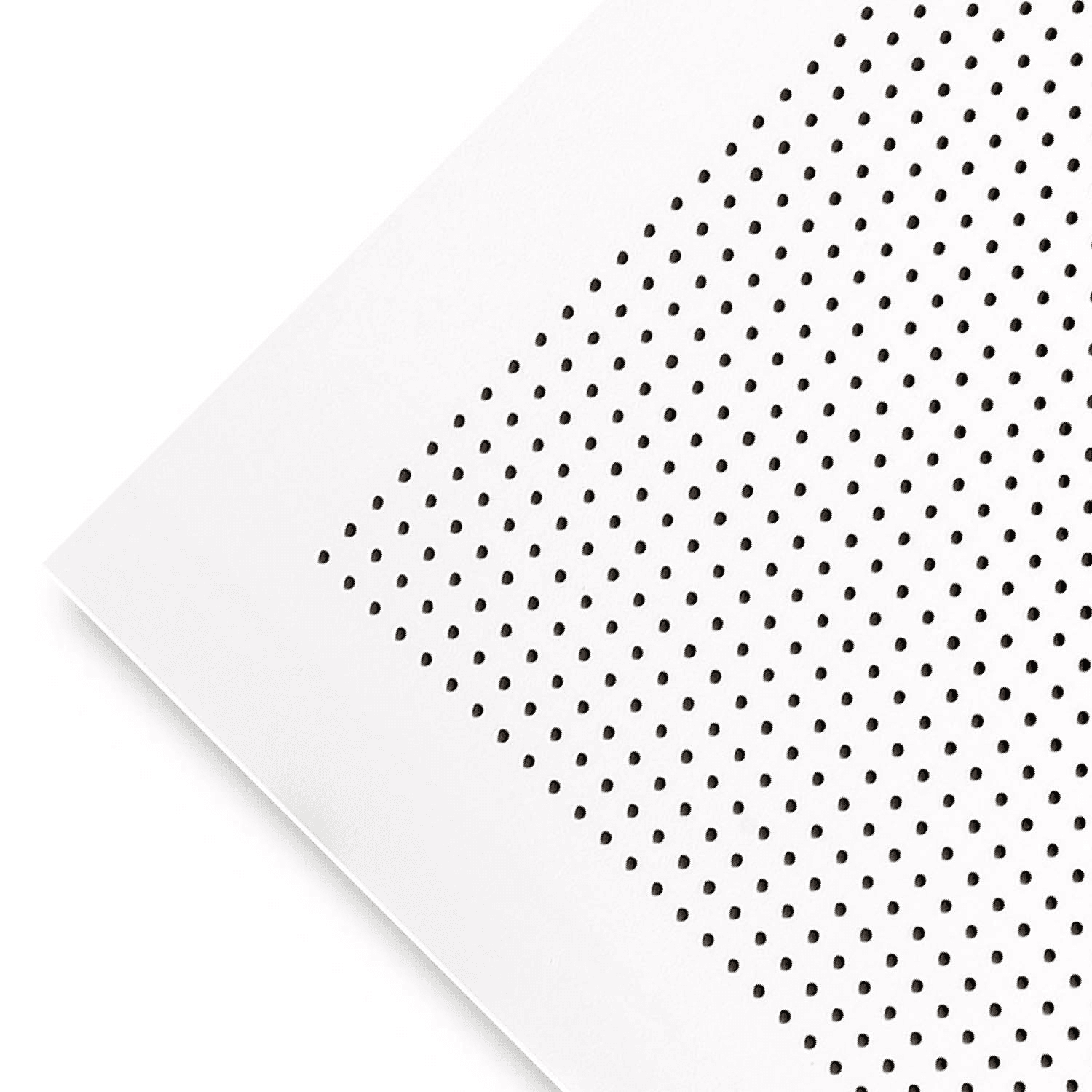

Gyprock Standard 6mm Round perforated plasterboard provides economical sound attenuation in a perforated design that has been proven in projects around Australia.

Product Overview

All boards in the Gyprock Perforated Plasterboard range have been designed for use on ceilings and walls where an increased level of sound attenuation and a high level of aesthetic appeal is required. The design features six large rectangular groupings per sheet, each with 2,100 x 6mm diameter perforations at 15mm centres to provide an open area of 8.3%.

The panel perforations, together with insulation, where used, reduce echo and noise reverberation to create more comfortable environments for work and leisure.

Standard 6mm Round provides an economical aesthetic solution for ceilings or walls and acoustic performance is adequate for most situations where moderate levels of attenuation are required.

It is supplied without an acoustic fabric backing, however installers may use a third party acoustic fabric to provide higher levels of acoustic performance if required.

Loading component...

Loading component...

Loading component...

Key Features

Acoustics

Absorbs sound into the ceiling and walls to prevent reverberation

Aesthetics

Acoustic performance with design freedom

Australian Made

Licensed by Australian Made Campaign Ltd

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

Install to manufacturer's recommendations as outlined in the relevant Installation Guide.