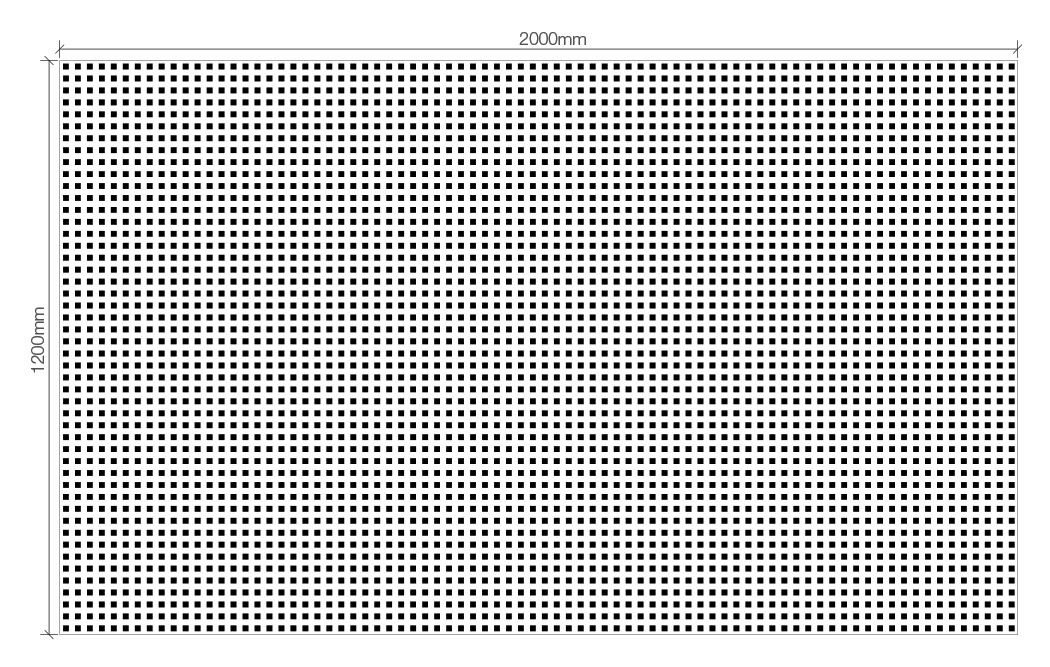

With a 23% open area Rigitone Matrix 12mm Square combines exceptional acoustic performance with modern monolithic design thanks to it's edge-to-edge perforation layout and unique installation method.

Product Overview

Manufactured by worldwide plasterboard specialist, Saint-Gobain, Rigitone is purpose built to provide exceptional acoustic control with ultimate design freedom. High levels of acoustic absorption are achieved through a combination of perforation patterns and a highly effective black acoustic fabric backing which also prevents dust from the ceiling entering the room and masks the ceiling framework.

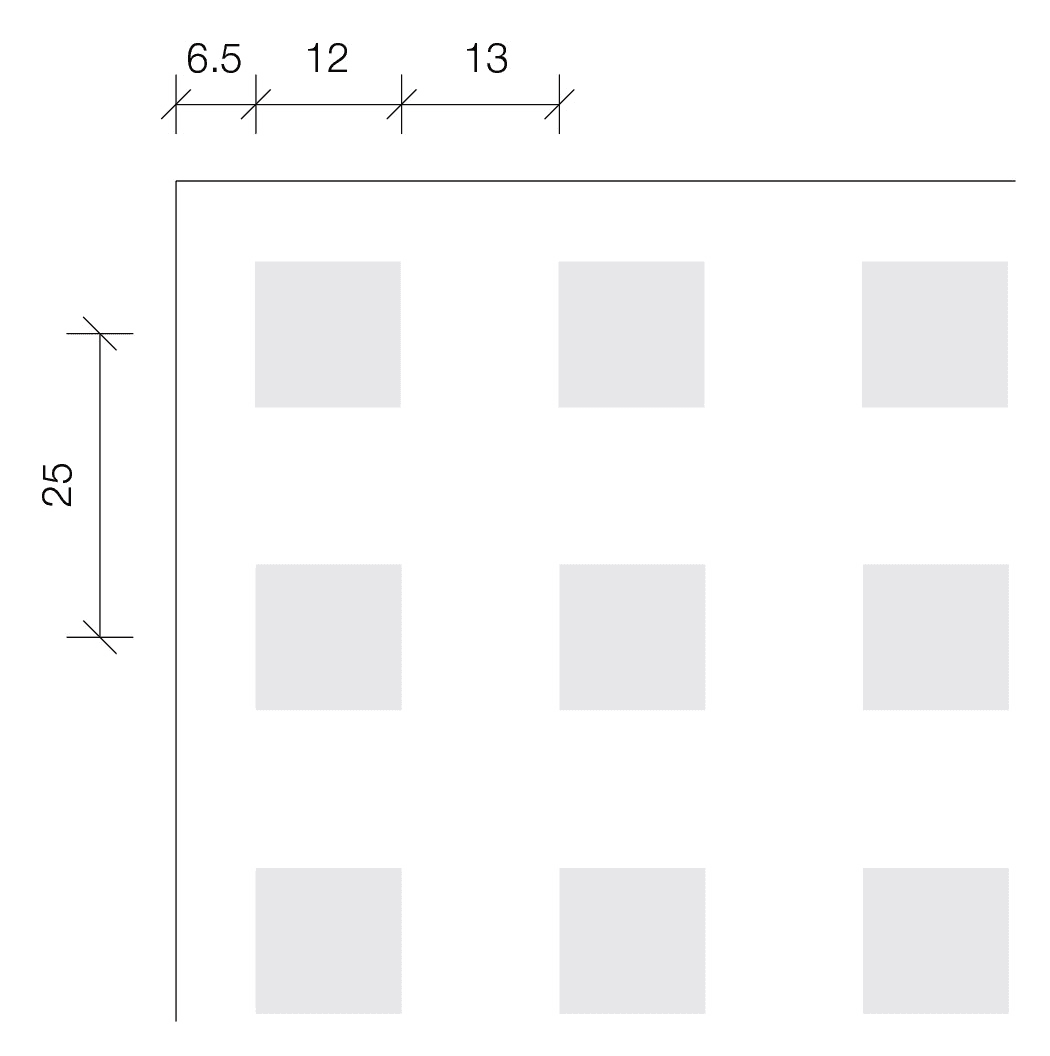

Rigitone Matrix 12mm Square provides a pattern of 12mm square perforations at 25mm centres, providing a 23% open area.

Rigitone is also manufactured with Activ’Air technology which has an enduring impact on indoor air quality. Rigitone Matrix 12mm Sqaure features the new Rigitone™ edge – a chamfered edge that connects directly to adjoining boards at the top, removing the need for a Rigitone Pattern Spacer and ensuring perfect alignment. Boards are pre-primed for a unique installation method using ready-mixed Rigitone Filler, creating a continuous, seamless finish. The availability of seamless access panels ensures easy access to the ceiling cavity while maintaining pattern continuity.

Loading component...

Key Features

Acoustics

Absorbs sound into the ceiling and walls to prevent reverberation

Aesthetics

Acoustic performance with design freedom

Healthy Environment

Activ'Air for enduring, cleaner air

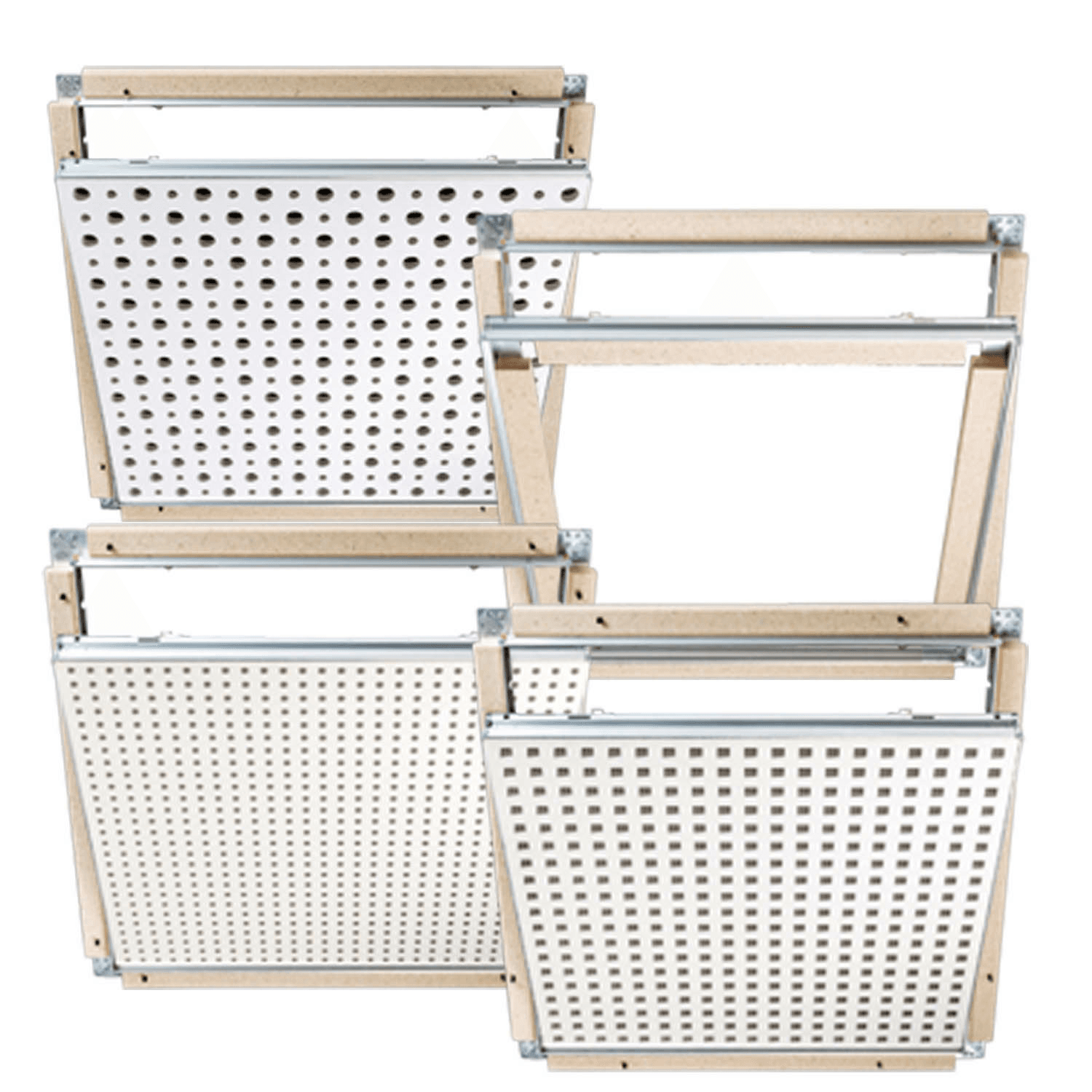

Access Panels

Rigitone Access Panels are integrated into suspended ceilings to allow for inspection, service and maintenance work on the installations in the space above. Gyprock offers an access panel solution for the Rigitone range that provides easy access and integrates seamlessly into the ceiling.

Loading component...

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

Install to manufacturer's recommendations as outlined in the below guide.