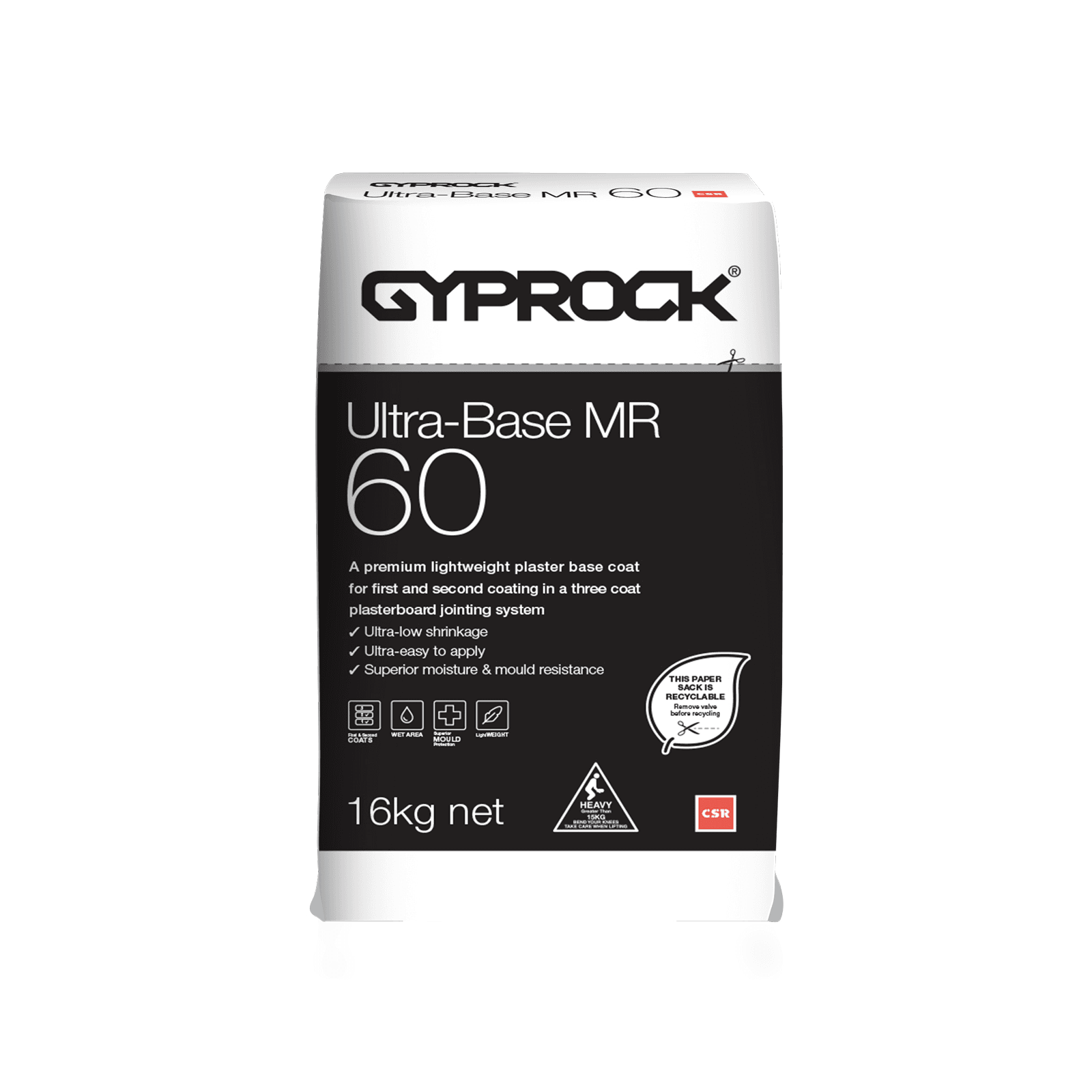

Gyprock Ultra-Base MR 60 is a premium lightweight base coat with superior moisture and mould resistance. The product is tinted light blue for easy identification on the job.

Product Overview

Gyprock® Ultra-Base MR 60 is a setting type base coat formulation with a working life of approx 60 minutes from application. It is for the jointing of Gyprock plasterboard in all areas of the home. Its lightweight formulation is ultra-easy to apply and it offers enhanced moisture and mould resistance, making it ideal for use with Gyprock Aquachek™ in wet areas and protected exterior applications such as alfresco areas. Joints may be finished with any Gyprock topping or all-purpose compound and sanded smooth prior to decoration.

Loading component...

Key Features

Australian Made

Licensed by Australian Made Campaign Ltd

Powerful Antifungal Agent

Resists mould and mildew

Hand and Machine Tool Applied

Easy application with a range of tools

Moisture Resistant

Suitable for wet areas

Compound Selection

Loading component...

Loading component...

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

AS/NZS2589: Gypsum linings – Application and Finishing outlines the procedures for the installation and finishing of Gyprock Perforated Plasterboard in conjunction with additional details contained in Gyprock Technical Literature.