Gyprock Easy-Flow is lightweight all-purpose jointing compound specially developed for mechanical application, with excellent tape adhesion, trowelling and feathering properties.

Product Overview

Easy-Flow is a versatile all-purpose jointing compound used for all coats in a three coat jointing system. This low VOC formulation is available in a convenient premixed form that has been developed to provide exceptional out-of-machine flow for mechanical application.

Each coat dries and hardens in approximately 24 hours ready for recoating or sanding.

Typical Applications

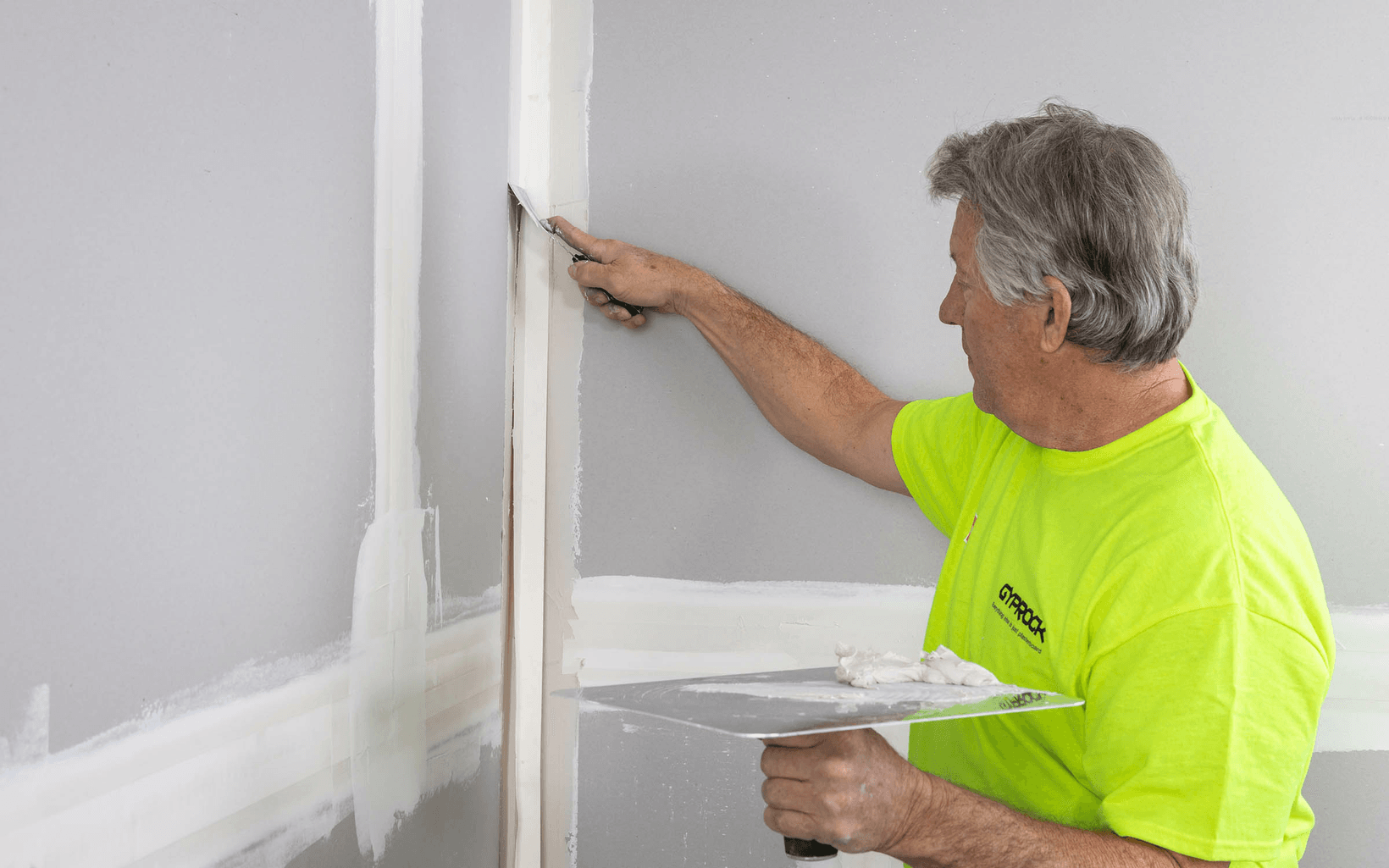

Gyprock Easy-Flow is typically used for each coat in a three coat jointing system in residential and commercial walls and ceilings. It is specifically designed for application with mud boxes, automatic tapers and other machine tools.

Key Features

Australian Made

Licensed by Australian Made Campaign Ltd

All-purpose

Use for all coats of a 3 coat joint system

Pre-mixed

Quick to prepare, easy to apply

Exceptional Flow

Ideal for machine application

Compound Selection

Loading component...

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

AS/NZS2589: Gypsum linings – Application and Finishing outlines the procedures for the installation and finishing of Gyprock Perforated Plasterboard in conjunction with additional details contained in Gyprock Technical Literature.