For internal linings where the highest impact resistance is critical in a multi-attribute board, such as Health Care projects especially Mental Health Facilities, as well as Correctional Facilities, Sporting Facilities, Schools and Hotels.

Product Overview

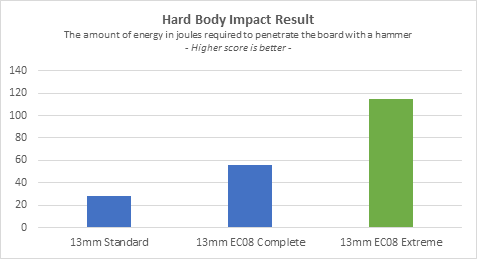

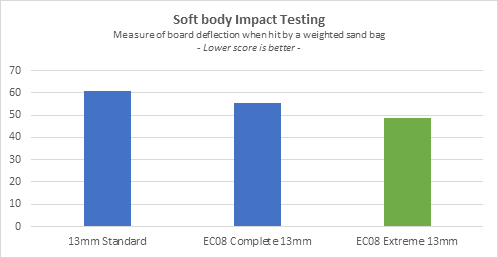

Gyprock EC08™ Extreme is an Australian made, GECA certified, multi-function plasterboard with the highest level of specifications in the EC08™ range. It has been specifically designed to meet the highest standards across a broad range of performance requirements, but with a focus on superior impact resistance.

This low VOC board is manufactured with a layer of fibreglass mesh in addition to a dense, fibre-reinforced core and high grammage face paper, which means EC08 Extreme walls offer extreme resistance to damage of all types and stay looking newer for longer. This can result in a reduction of regular and unplanned maintenance, saving ongoing operational costs to the building.

EC08 Extreme is easily identified by its green coloured face paper.

Loading component...

Loading component...

Loading component...

Key Features

Australian Made

Licenced by Australian Made Campaign Ltd

Extreme Impact Resistance

Reduces damage from hard and soft body impact, and surface indentation

Powerful Antifungal Agent

Resists mould and mildew

Moisture Resistance

Suitable for wet areas

High Recycled Content

Ideal for green building projects

Acoustic Properties

Helps combat sound transmission

Fire-rated

Can be used as part of a fire-rated system

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

Install to manufacturer's recommendations as outlined in the relevant Installation Guide.