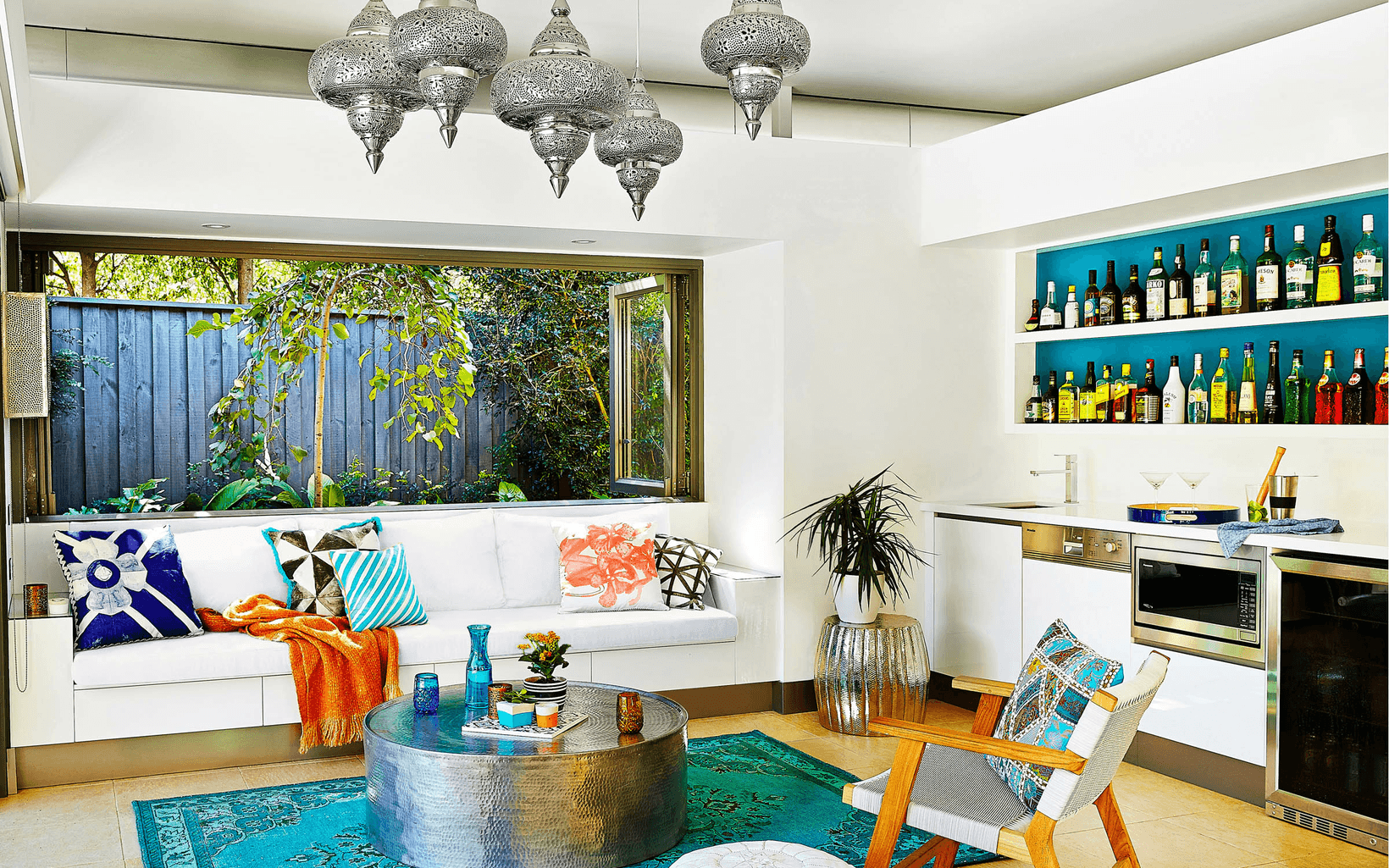

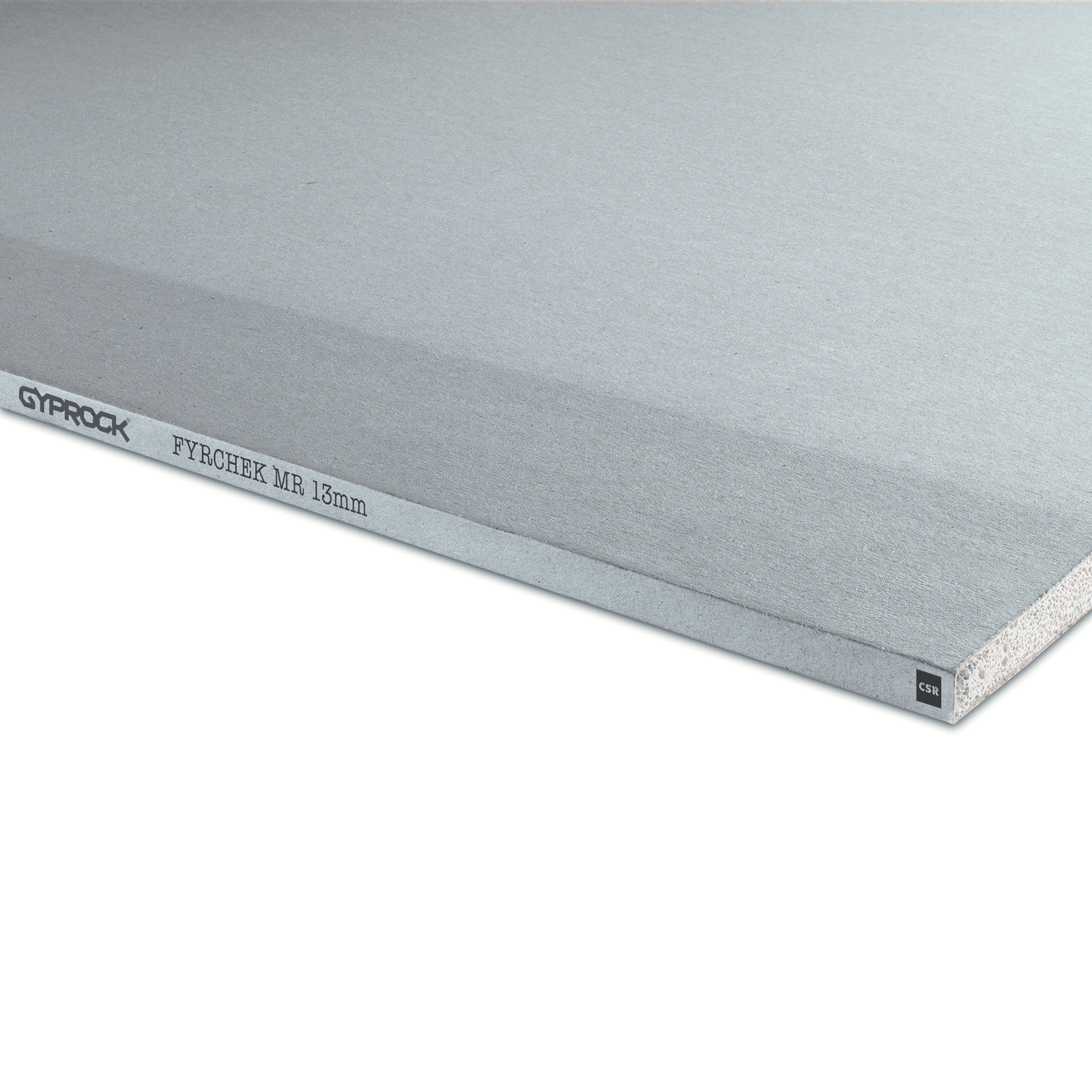

Gyprock Fyrchek MR combines a fire and acoustic grade board with additional moisture resistance to create the ideal lining for fire rated wall and ceiling systems in wet areas.

Product Overview

Fyrchek MR’s glass fibre-reinforced core enables it to maintain structural integrity when subjected to direct flame. The additional moisture resistant properties make it an ideal board for use as part of a fire rated wall or ceiling system in wet areas or application subjected to high humidity.

This plasterboard is also an acoustic grade board and can be used in systems where acoustic separation is specified.

Gyprock Fyrchek MR can be easily identified by its blue coloured face paper.

Loading component...

Loading component...

Loading component...

Key Features

Moisture Resistant

Suitable for wet areas

Fire Resistant

Can be used as part of a fire-rated system

Acoustic Properties

Helps combat sound transmission

Australian Made

Licensed by Australian Made Campaign Ltd

Loading component...

Loading component...

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

Install to manufacturer's recommendations as outlined in the relevant Installation Guide.