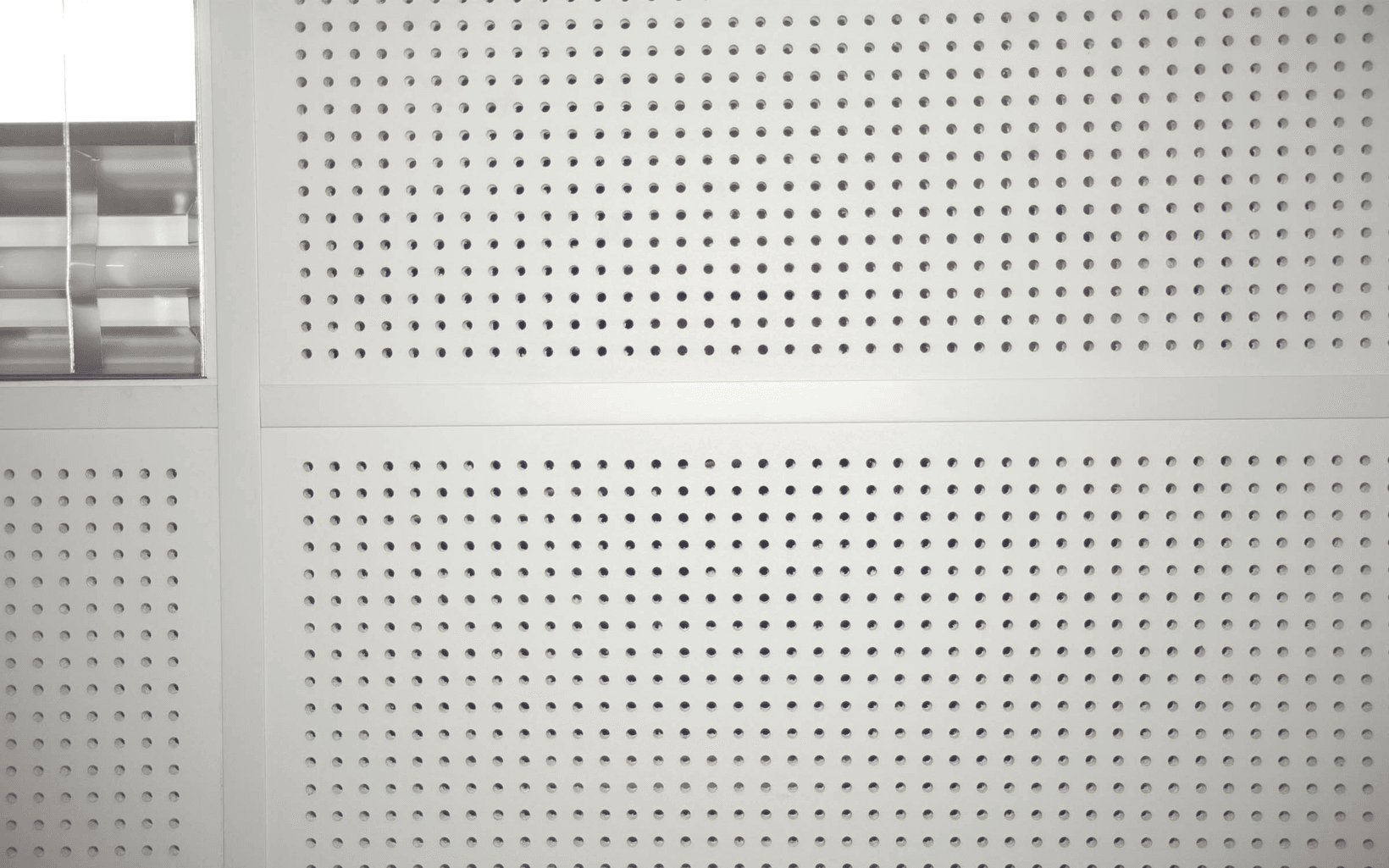

Gyprock Perforated Ceiling Tiles come in a white vinyl laminate finish, providing superior sound absorption for acoustic control in commercial grid ceilings.

Product Overview

Perforated Ceiling Tiles are squared edged, 13mm thick and available as 1200mm x 600mm tiles to suit common exposed grid systems. The acoustic properties of the tiles are achieved by a regular grid of 6mm, full depth holes to approximately 10% of the panel area. This, combined with suitable insulation, provides a medium level of sound absorption to reduce echoes and reverberation. The edges of the tiles are cut square to suit exposed grid ceiling systems. The white vinyl facing is easy to clean.

Loading component...

Loading component...

Loading component...

Key Features

Australian Made

Licensed by Australian Made Campaign Ltd

Acoustic

Perforated for enhanced acoustic absorption

Easy to Clean

Vinyl facing for easy cleaning

Drop-in Tile

Suitable for suspended grid systems

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

Install to manufacturer's recommendations as outlined in the relevant Installation Guide.