Gyprock Back-Blocking Cement is a specially formulated plaster based cement used for reinforcing plasterboard joints where there is no framing support.

Product Overview

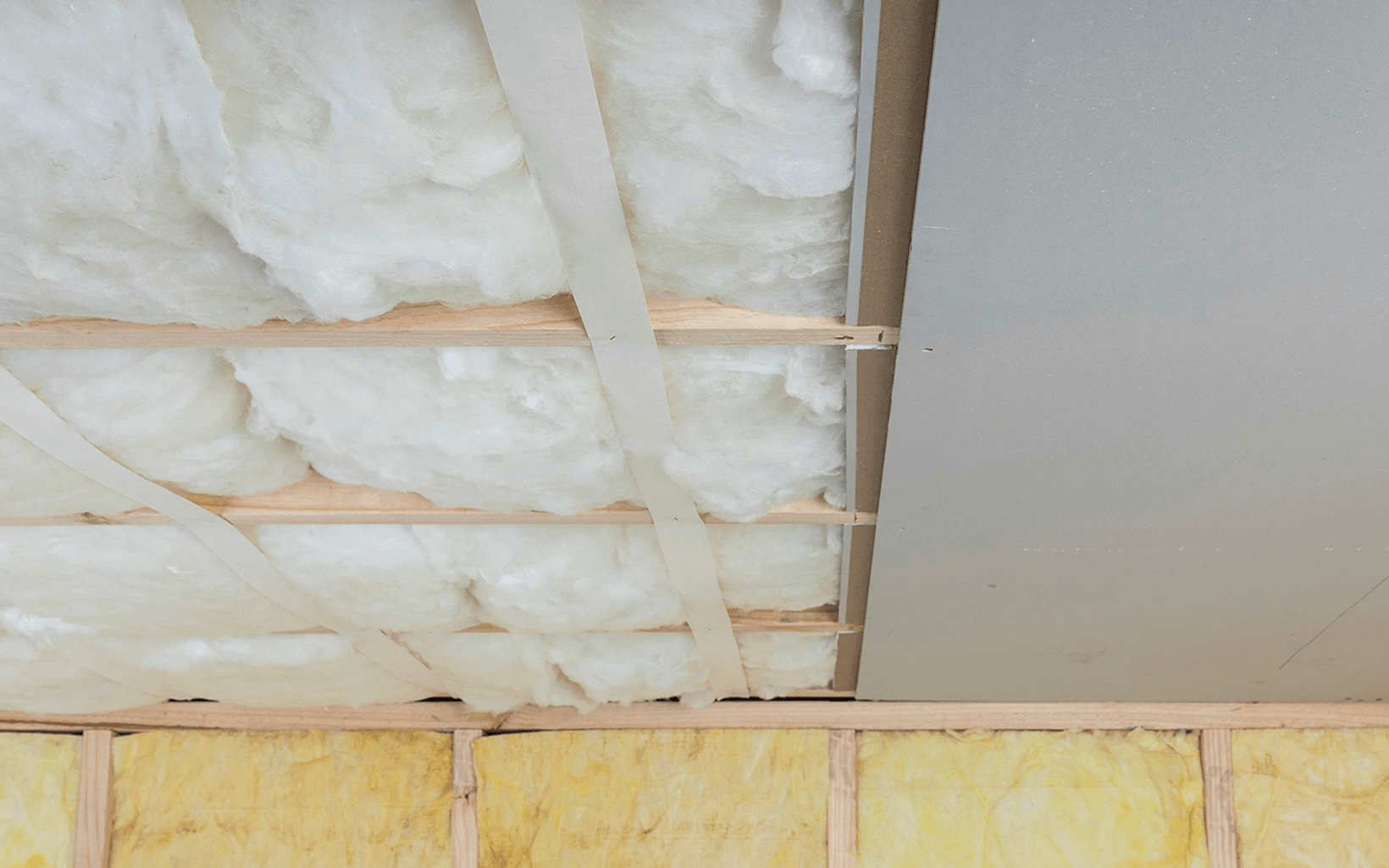

Gyprock Back-Blocking Cement is a simple and convenient way to adhere supporting back-block strips behind joints in plasterboard sheets where there is no framing to fix to. Back-blocks are plasterboard off-cuts at least 200mm wide and long enough to fit between the framing members.

It is specially formulated to offer excellent adhesion properties and to minimise the risk of joint cracking or distortion.

Gyprock Back-Blocking Cement supplied as a dry powder and is easy to mix and apply by hand using a notched trowel. It has a 2 hour working life once mixed.

Loading component...

Loading component...

Typical Applications

Gyprock Back-Blocking Cement is used to adhere back-blocks to strengthen joints where there is no framing to fix to. It is typically used in butt and recessed joints in ceilings and walls.

Key Features

Acoustic Properties

High acoustic rating when used in a system

Superior Adhesion

Good initial grab and excellent adhesion properties

Easy Application

Easy to mix and apply

Defined Setting Time

2 hour working life

Technical Specifications

Loading component...

Loading component...

Loading component...

Loading component...

Installation Instructions

AS/NZS2589: Gypsum linings – Application and Finishing outlines the procedures for the installation and finishing of Gyprock Perforated Plasterboard in conjunction with additional details contained in Gyprock Technical Literature.