Australian Made

Gyprock has partnered with Australian Campaign (AMCL) to promote Australian manufacturers in the building and construction industry. Gyprock pioneered plasterboard in 1947, and transformed the building industry in Australia with the introduction of paper-faced plasterboard. Today, Gyprock continues to drive innovation, influencing trends in the home design, commercial and architectural space.

Loading component...

Loading component...

Loading component...

Partnerships

Gyprock maintains its market leading position by choosing to partner with leaders in the fields of product and market development. Strong relationships with a number of organisations in Australia and around the world ensure Gyprock provides the best solutions for the industry's needs.

Loading component...

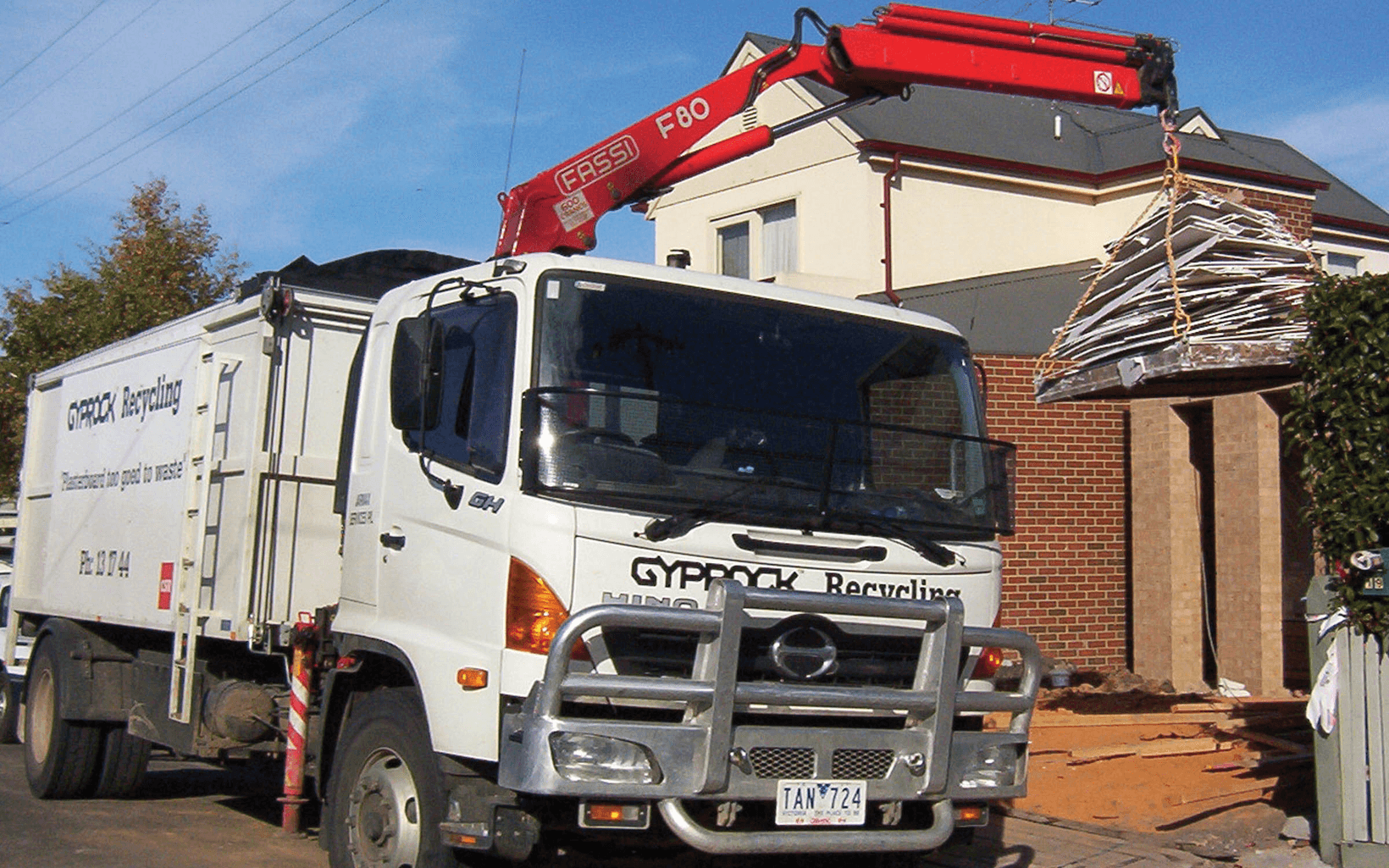

Plasterboard Recycling

Gyprock actively supports plasterboard recycling both to help the environment by reducing waste going to landfill and also because it is often a great way for builders to save on waste tipping fees and site clean up costs as well as improve site safety with better resource management.