Gyprock Shaft Systems are non-loadbearing, fire resistant wall assemblies designed to encase lift shafts, stairwells and service ducting in low and high rise construction.

Gyprock Shaft Systems combine lightweight construction, rapid installation and plasterboard finishing techniques to offer significant cost savings to builders and developers particularly when combined with structural steel construction. They are designed predominantly for erection from one side only. Walls are assembled from outside the shaft at each floor, eliminating the need for access or scaffolding within the shaft.

Applications

A comprehensive range of Gyprock Shaft Systems is available to accommodate most common applications. Gyprock Shaft Systems are predominately used for lifts, stairwells and shafts for air conditioning ducting and other services.

System Advantages

- Rapid installation

- Lightweight

- Space efficient

- Easy materials handling

- No wet trades required

System Performance

Shaft Wall systems can play a critical role in a building. They are responsible for ensuring the safety of occupants in the event of a fire and they need to reduce the transfer of noise associated with lifts and mechanical services.

Loading component...

Loading component...

System Design

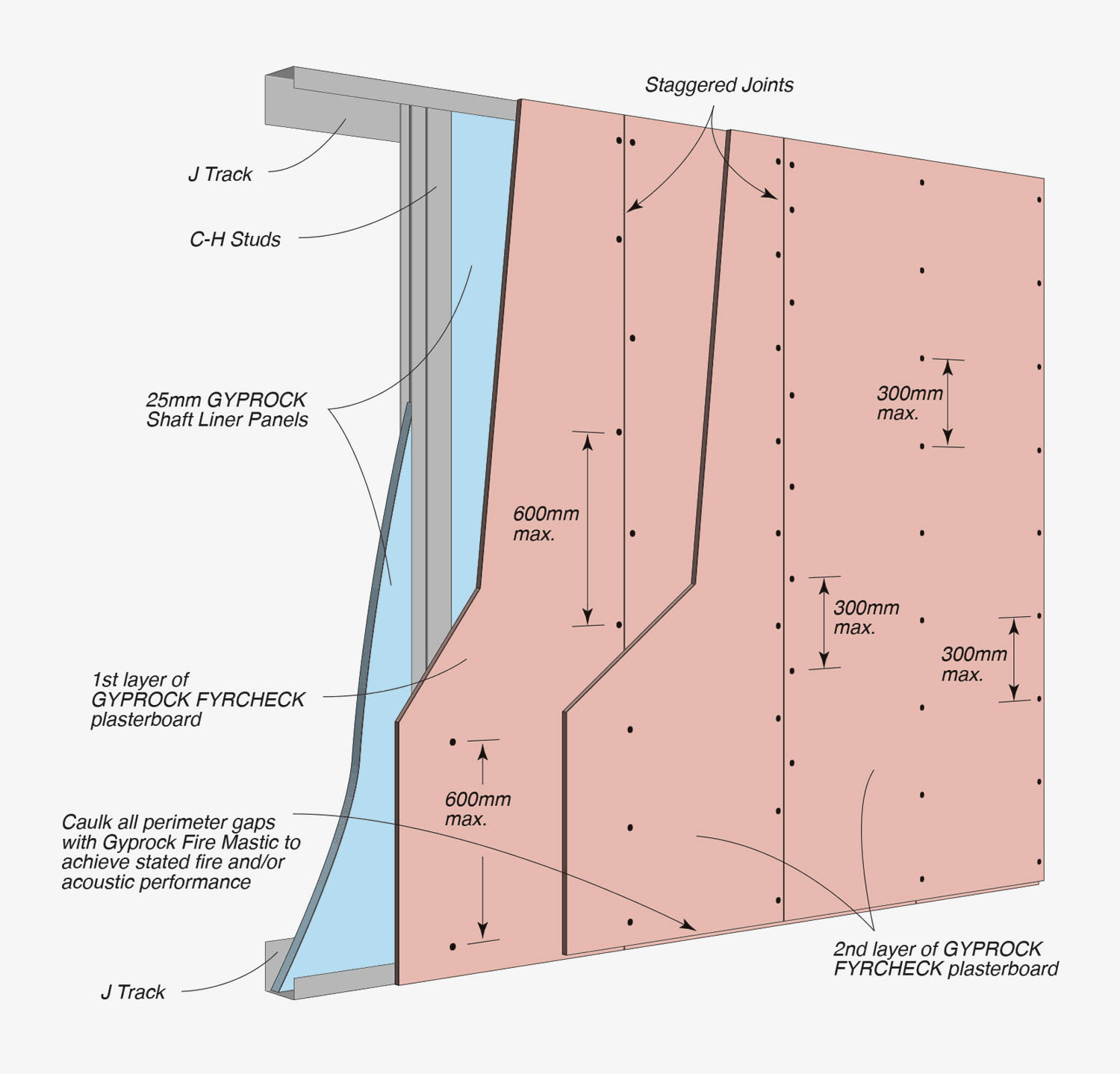

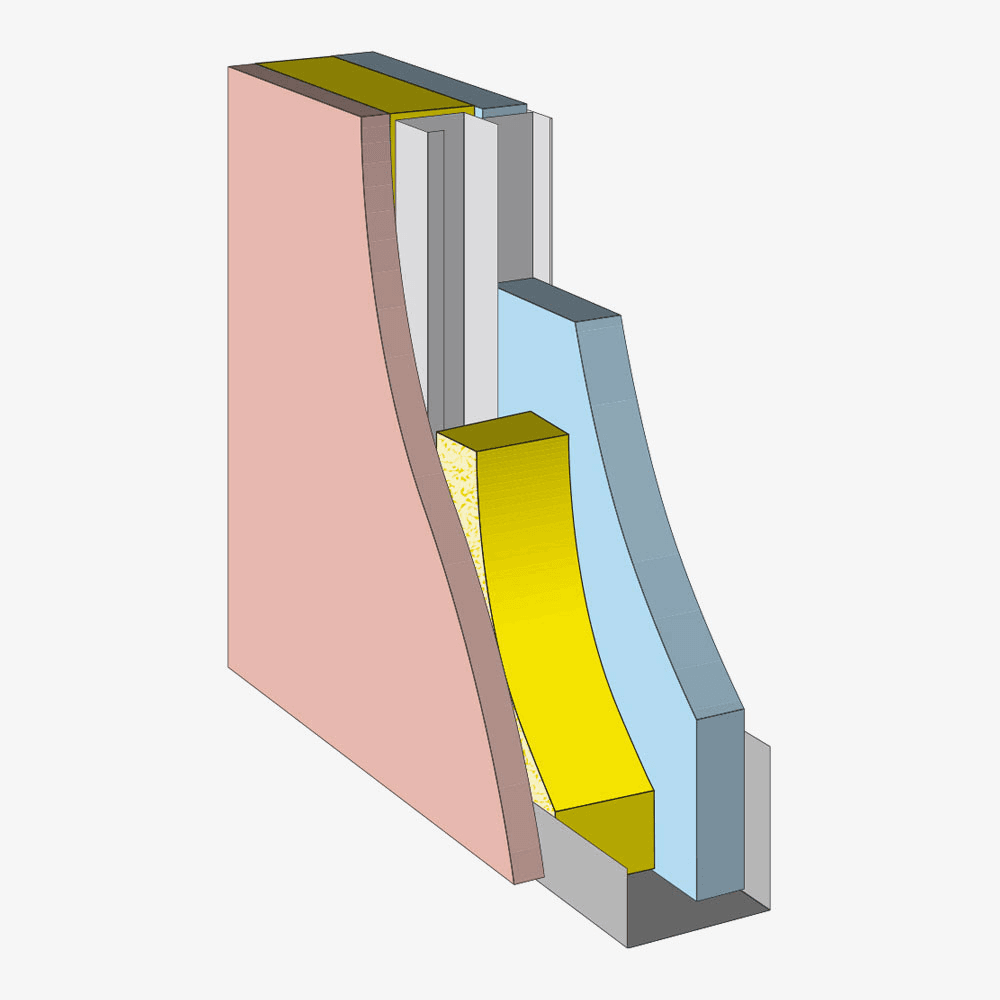

These diagrams show three typical layout options for the StrataWall system. The Gyprock Red Book outlines a comprehensive list of layout options and can help you find a design that works best for your building performance needs.

Loading component...

Loading component...

System Components

Gyprock Shaft Wall systems include a range of lining, insulation and accessory options to be determined by the designer in order to achieve different performance requirements. Only those product options specified should be used in order to guarantee the fire and acoustic performance of the system.